With the continuous development of the tv backlight strip industry, our company has become increasingly strict in its requirements for product reliability. Recently, our company has even launched a standardized testing scheme based on the pointer-type digital display push-pull force spring force gauge, specifically designed to test the bonding strength between the lens and the substrate of the backlight strip. This scheme can accurately quantify the firmness, help manufacturers improve product quality, reduce the risk of delamination, and provide customers with higher-quality product services.

With the development of this industry trend, Mr. Guan, the chairman of Starsharp, stated: "As experts in the field of led tv backlight strips replacement, we must be able to provide customers not only with shorter delivery times, but also ensure the high quality of the products, and not le0t down the trust they have placed in us."

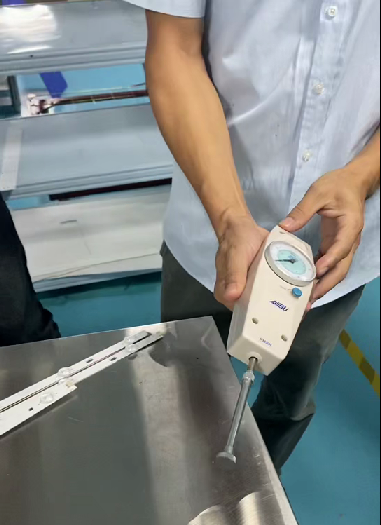

(The above is our staff using a spring tester to test the adhesion of the light strips)

Using a pointer-type digital pull-force spring force gauge to test the bonding strength of the lens of the lamp strip is of great significance.

Firstly, in terms of technical significance, testing the bonding strength can address industry pain points, quantify the bonding force, and replace subjective judgment.

Traditional methods relying on visual inspection, manual manipulation, etc. cannot provide precise data. However, the force gauge directly quantifies the bonding strength in units such as Newton (N) or kilogram force (kgf), eliminating human errors. It can also prevent potential failure risks. Lens detachment is one of the common faults in LED lighting. By conducting tests, one can detect batches with poor bonding in advance, avoiding product failure during transportation, in high-temperature and high-humidity environments, or after long-term use. More importantly, it optimizes the production process. By comparing test data of different glue types, curing times, or surface treatment methods of the substrate, the best bonding solution can be found.

The second aspect is the commercial significance. By doing this, not only can the probability of the lens falling off be reduced, but it can also assure the customers of our company's quality requirements for the product production, making them more confident in purchasing from us.

Finally, there is the aspect of sustainability. Spring pressure tests can ensure product reliability, reduce customer risks, and prevent failures caused by delamination. Through scientific testing, customers can ensure that the product maintains structural stability during transportation, installation, and long-term use. At the same time, it can reduce the cost of after-sales maintenance. Customers (such as engineering contractors, brand owners) can significantly reduce hidden costs such as returns, repairs, and compensation due to quality issues.Reference data: After an LED manufacturer introduced the test, after-sales claims decreased by 40%.

It can also enhance the customer's brand reputation and win the trust of end users. Customers can publicly promote "Each batch of products undergoes a test of XX Newton pulling force", strengthening the brand image of "durable and high reliability", especially standing out in the high-end market.Customers can also optimize their supply chain management, helping them achieve long-term cost optimization and gain competitive support in differentiated markets.

In conclusion, using a spring tester to test the adhesion of the light bar lenses not only helps Starsharp establish a good reputation in the market for its tv backlight light bars, but also enables our customers to feel confident when purchasing and using them, and gives them the assurance of long-term cooperation with us.